Nanofluidics and Microfluidics

Specific research include:

Analysis and Review of Micro-Cooling and Lab-on-a-Chip Devices

The demand for high-efficiency performance and compact design of devices in modern mechanical, chemical, and biomedical engineering puts a premium on effective microsystem cooling. Still, limited heat transfer rates can be one of the major obstacles for microsystems, which may generate significant heat fluxes. One way to overcome this difficulty is to use novel coolants with better thermal performance than convectional fluids such as oil, water, or ethylene glycol. For example, adding solid nanoparticles (NPs) to the liquids at low volume fractions creates a new type of fluid–particle mixture that may substantially enhances heat transfer rates. Thus, the resulting nanofluid, that is, a dilute NP suspension in liquids, is deemed promising as a solution to the cooling problem of microsystems.

Similarly, small hydraulic diameter in microchannels limits the Reynolds number to a very small value, precluding turbulent dispersion. Hence, mixing process is limited by the small diffusion coefficients of the species and the dominance of viscous effects. Mixing of two fluid streams is an important microfluidic application since good mixing needs to be achieved quickly and within a reasonable channel length, without consuming much power. Lab-on-a-chip devices and DNA microarrays are examples of microfluidic applications in clinical diagnostics and targeted drug delivery systems.

Hence we are interested in understanding and improving mixing and heat transfer in microfluidic and nanofluidic devices. Following are some of the research project examples:

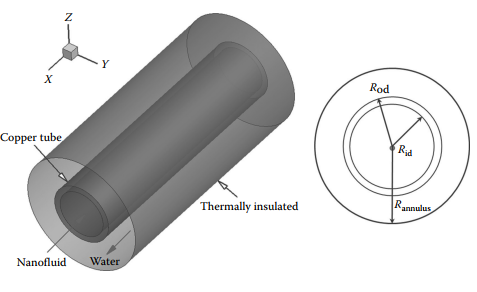

Double-tube Heat Exchanger

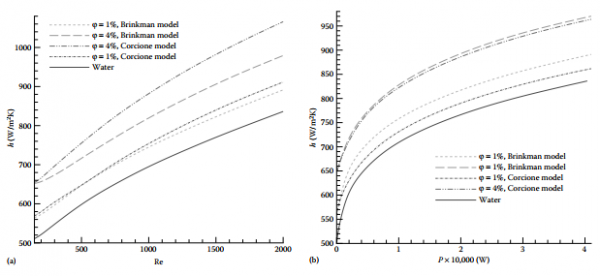

We investigated the double-tube heat exchanger configuration, as shown below, with hot water flowing in the annulus; cold nanofluid flowing in the inner tube exchanging heat with water through a copper tube wall in between. Our analysis confirmed that nanofluid flow yields higher heat transfer coefficient than pure water flow at the same Reynolds number and under the same pumping power, as can be seen in figure below. We demonstrated that under constant pumping powers, nanofluids still generate higher heat transfer coefficient than water, which suggests that the gain from increased thermal conductivity overweighs the loss from increased viscosity.

Nanofluid Cooling of Concentration Photovoltaic–Thermal (CPV/T) Systems

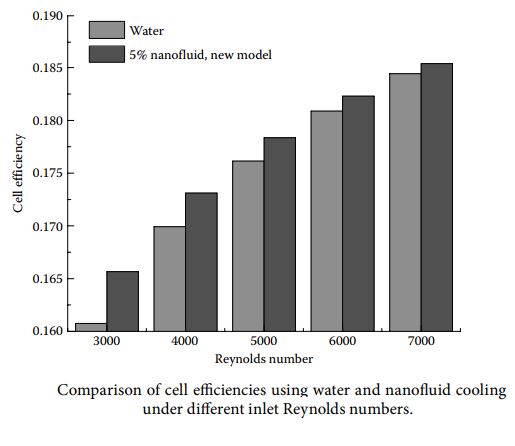

New designs of dual concentration photovoltaic–thermal (CPV/T) systems can provide both electrical and thermal energy, while reducing solar cell material usage via optical techniques. The overall system efficiency can be improved by using advanced dual-purpose liquids with enhanced heat transfer characteristics, such as nanofluids.

Nanofluids generate better heat transfer performances than the base fluids alone, due to higher thermal conductivities resulting from Brownian motion effects. This means higher cell efficiencies (i.e., lower cell temperature) using nanofluid cooling. However, our results indicated that the this efficiency gain becomes smaller when the Reynolds number increases.

An effective method for operational and/or geometrical optimization of thermal systems is by minimization of the entropy generation. So to further improve the thermal system, one could study the the effect of the NP volume fraction, the inlet Reynolds number, the channel height, as well as the nanofluid inlet temperatures on the entropy generation due to both friction and heat transfer.

Y-shaped Sinusoidal Micro-channel

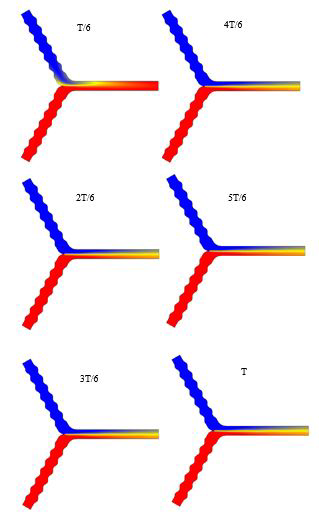

As an example we investigated the mixing and heat transfer between two nano-fluid streams in a Y-shaped sinusoidal micro-channel. Our simulations indicated that modifying the geometry with wavy walls and by taking advantage of the flow instabilities created by the modifieded geometry and pulsating flow, yields the highest degree of mixing and heat transfer within the listed constraints.

Schematic diagram of the sinusoidal micro-channel.

Average degree of mixing along the outlet channel